Insulation R-values and cavity depths

Our homemade

storage building

continues to be a learning experience. When we started out, I

blithely said, "Let's put in as much insulation as possible despite the

cost," and Mark agreed. What I didn't realize is that you have to

plan for your insulation needs from the get-go.

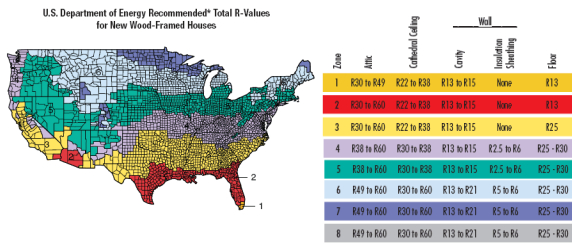

The map and chart at the

top of the page show EPA's insulation recommendations for new

wood-framed homes when heating with gas, heat pumps, or fuel oil.

(They recommend more insulation if you heat with electricity, and don't

even give you an option for heating with wood.) We're in their

zone 4, which means we should have at least R30 in our ceiling and R13

in our walls. The latter is easy, but the former is a bit of an

issue.

Assuming

you're using fiberglass insulation (which fits our wallet and

our remote setting), you need thicker wall or ceiling cavities to fit

more insulation. A typical 2X4 wall will hold up to R15 --- if

you try

to cram R19 in, you compress the insulation and, I believe, actually

get less insulative value than you would have with a lower rated batt

of insulation.

Assuming

you're using fiberglass insulation (which fits our wallet and

our remote setting), you need thicker wall or ceiling cavities to fit

more insulation. A typical 2X4 wall will hold up to R15 --- if

you try

to cram R19 in, you compress the insulation and, I believe, actually

get less insulative value than you would have with a lower rated batt

of insulation.

Our original rafters are 5.5 inches deep, which

would only allow us to put in R19 insulation up there --- makes me

chilly just thinking about it (although I think the trailer ceiling has

about R13.) So we extended our rafters with some two by fours,

giving us the space to increase our ceiling insulation to R30.

For future reference, here is the cavity depth you need for some common

insulation r-values:

- 3.5 inches --- R13

- 6 inches --- R19

- 9 inches --- R30

- 12 inches --- R38

Most of our building

project has been very forgiving of my learn-as-we-go mentality, but

insulation requires some forethought. For those who might want to

try their own hand at building --- shun the fault I fell in!

Want more in-depth information? Browse through our books.

Or explore more posts by date or by subject.

About us: Anna Hess and Mark Hamilton spent over a decade living self-sufficiently in the mountains of Virginia before moving north to start over from scratch in the foothills of Ohio. They've experimented with permaculture, no-till gardening, trailersteading, home-based microbusinesses and much more, writing about their adventures in both blogs and books.

Want to be notified when new comments are posted on this page? Click on the RSS button after you add a comment to subscribe to the comment feed, or simply check the box beside "email replies to me" while writing your comment.

I totally agree! That's why it was the one part I was willing to spend money on.

(By the way, you should have signed in, then you could have commented without being moderated!)

Don't forget to add a moisture barrier, at least in the loft. The preformance of most insulating materials (with the exception of closed-cell foam) drops a lot when it gets damp. And you can get mold problems as well.

Here in the Netherlands, a moisture barrier is usually added on the inside of the insulation, because humans in this case can be seen as leaky bags of dirty water. For a wooden building it might be different, I don't know. Check your local building code.

For a wooden building it might be different, I don't know. Check your local building code.

P.S. Cans of spray foam are excellent at sealing gaps and preventing draft, and the material also adds insulation and acts as a moisture barrier.

Don't seal all the cracks, or you might get more mushrooms than you've bargained for. Inside, that is.

Stuff like tyvek is excellent. It keeps cold air out, but lets moisture pass from the inside out as well. I'm all for natural materials when they work, but sometimes modern synthetics are just way better.

For example, when I'm commuting to work on my bicycle, I tend to wear a polyester t-shirt and a softshell jacket. Which probably sounds really cold. But the polyester wicks the sweat away from the skin and the softshell material keeps the wind out but lets the moisture escape. So I'm dry and therefore warm. Only when it gets below freezing I have to add another layer like a fleece sweater. When I was still wearing a cotton t-shirt I always arrived at work practically soaked, and in the winter cold as well.

I'm not knee-jerking against synthetics so much as against anything that costs extra. We've put plenty of synthetic parts into the building (like the fiberglass insulation.) But given that there is a controversy about both house wrap (as being mostly a quick fix to deal with water seeping through cracks in metal siding, which we don't have) and vapor barriers (as being possibly more harm than good in mixed climates like ours), I think we'll be fine with just putting in what's on the insulation.

I do appreciate y'all's concern, even if I'm ignoring it.