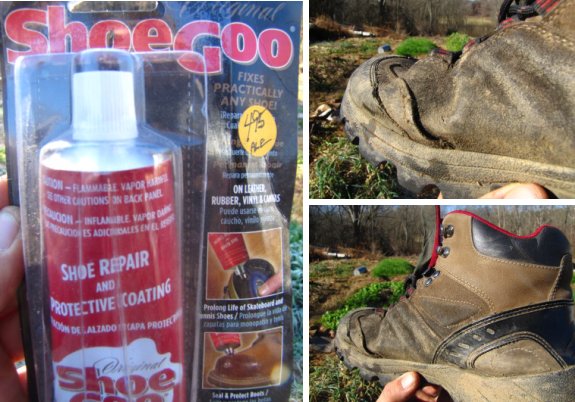

Shoegooreview

The work load here on Wetknee

farm has proven to be rough on work boots.

I thought an expensive pair

of Timberlands would last

longer. Turns out they started to fail within the same time frame as

cheaper boots which prompted me to keep going with Ozark Trail, which usually sells

for 30 dollars but can sometimes be found for 20.

The weak point is always

where my toes bend. This time I tried to extend the life of the above

pair with a product called Shoe Goo.

I made sure they were nice and dry and applied a liberal amount within

the gaps and gave it the full 48 hours of set up time.

My feet got wet the first day

just by stepping in puddles while chopping wood.

I think this product would

work well if you needed to re-attach the sole to the shoe as pictured

on the package. It might even form a decent protective coating to seal

up some shoes, but I don't think it's up to the task of bringing back

footwear that is so far gone they get your socks wet everytime you

cross the creek.

Want more in-depth information? Browse through our books.

Or explore more posts by date or by subject.

About us: Anna Hess and Mark Hamilton spent over a decade living self-sufficiently in the mountains of Virginia before moving north to start over from scratch in the foothills of Ohio. They've experimented with permaculture, no-till gardening, trailersteading, home-based microbusinesses and much more, writing about their adventures in both blogs and books.

Want to be notified when new comments are posted on this page? Click on the RSS button after you add a comment to subscribe to the comment feed, or simply check the box beside "email replies to me" while writing your comment.

My granddad, who was a tulip farmer used to wear traditional Dutch all-wooden clogs all year round on the farm. In the winter with woolen socks and straw for warmth. These one-piece wooden shoes are pretty much waterproof, so your feet won't get wet. And they work as safety shoes too!

Modern farmers probably swear by a pair of wellies.

Wow, it sounds like you all have a lot of experience with both shoes and goo. Rebecca's suggestion makes a lot of sense --- work boots do tend to have very tough soles so that you won't wear through them. I'll have to check out Stephanie's suggestion too --- I've never had luck getting rubber boots to last more than a couple of months, but maybe special mucking boots are the solution? Fascinating about the clogs --- we had a small wooden clog when I was a kid, and I always thought it looked highly uncomfortable, but I can see how it might be more utilitarian if made right.

Rebecca's suggestion makes a lot of sense --- work boots do tend to have very tough soles so that you won't wear through them. I'll have to check out Stephanie's suggestion too --- I've never had luck getting rubber boots to last more than a couple of months, but maybe special mucking boots are the solution? Fascinating about the clogs --- we had a small wooden clog when I was a kid, and I always thought it looked highly uncomfortable, but I can see how it might be more utilitarian if made right.

If we need to reattach soles, sounds like we should go back to shoe goo --- thanks for the firsthand experience, Shannon and Brandy!

Not all rubber boots are created equal. Boots being advertised as "rubber" can be made from modified natural rubber, injection moulded PVC or polyurethane ("PU") and maybe others. All rubbers (elastomers) eventually break down under the influence of UV and other outside inflences, because they are somewhat poreous. I think natural rubber is the most tear resistant, but tends to break down easier. Some plasticizers used in PVC have possible health issues. PU can be very elastic and tear resistant, but might be more expensive.

When looking for leather boots, you should look for work boots where the front of the foot is covered by a single piece of leather without stitches. Of course leather needs more maintenance than rubber. Boots with steel toe caps will aleays tend to tear just where the toe cap stops, due to the difference in flexibility between the materials.

Have a look at motorcycling boots. Most of those have a zipper to the bottom so they are easy to get in and out of, and they have a waterproof liner (gore-tex, running behind the zipper) these days. Military surplus boots might also be an option to look at.