Fixing a walk behind mower rewind starter

The pull rope on the mower

stopped doing its job about 10 minutes after I

fixed the rear wheel problem.

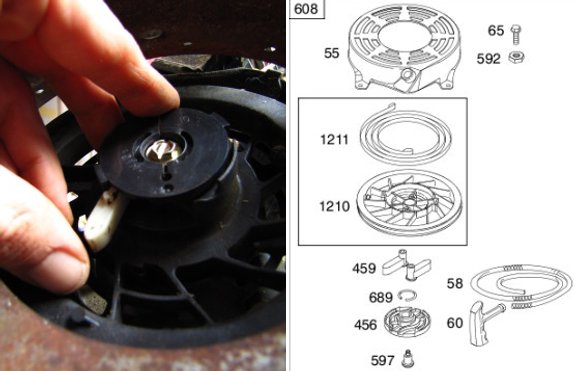

Most rewind starters have 2

white plastic fingers that extend out and grab when the rope is being

pulled and retract when the rope is released and its spring sucks it

back in.

These plastic fingers and the

groove designed to hold them are worn, causing the fingers not to

extend, and now when you pull on the rope nothing happens.

You can get the whole

mechanism for just under 40 dollars from Briggs and Stratton, which is

what I ordered. I was able to use sand paper to smooth out the rough

parts of the plastic to get it going for now, but I suspect it won't

last long due to the deformed groove.

Want more in-depth information? Browse through our books.

Or explore more posts by date or by subject.

About us: Anna Hess and Mark Hamilton spent over a decade living self-sufficiently in the mountains of Virginia before moving north to start over from scratch in the foothills of Ohio. They've experimented with permaculture, no-till gardening, trailersteading, home-based microbusinesses and much more, writing about their adventures in both blogs and books.

Want to be notified when new comments are posted on this page? Click on the RSS button after you add a comment to subscribe to the comment feed, or simply check the box beside "email replies to me" while writing your comment.

This particular Craftsman mulching mower has a Briggs and Stratton engine that has a model number of

123K02-0258-E1

which can be found engraved on a black metal plate on the metal cover holding the rewind starter and pull rope mechanism.