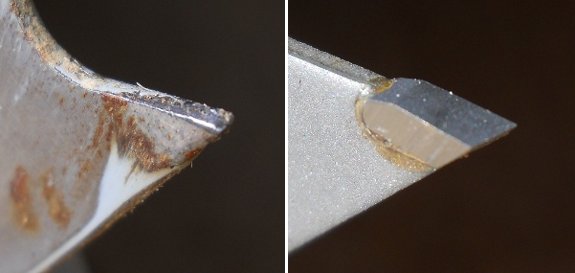

Dull blade close up

The main symptom of a dull

circular saw blade is the motor bogging down making cuts harder to push

through.

Above is a side by side

comparison of our old 12

amp Skil saw blade and a

brand new carbide tipped blade.

Maybe a circular saw from the

future will have a feature where it scans each tooth and shuts down or

beeps when the dullness is too much for the motor to handle.

Want more in-depth information? Browse through our books.

Or explore more posts by date or by subject.

About us: Anna Hess and Mark Hamilton spent over a decade living self-sufficiently in the mountains of Virginia before moving north to start over from scratch in the foothills of Ohio. They've experimented with permaculture, no-till gardening, trailersteading, home-based microbusinesses and much more, writing about their adventures in both blogs and books.

Want to be notified when new comments are posted on this page? Click on the RSS button after you add a comment to subscribe to the comment feed, or simply check the box beside "email replies to me" while writing your comment.

The old saw looks like plain steel. If you decide to sharpen that, take care not to overheat it. If the tip of the tooth is discolored after grinding, it might have changed its temper and become less suitable for a saw.

Saws already have a built-in guard against dull blades; it's called a fuse. If the saw is really blunt, the motor starts drawing too much current and the fuse will melt and break the circuit. Which is a good thing, otherwise the windings in the motor might short-circuit as the nonconductive coating on the wires degrades because of the heat.

If the saw is really blunt, the motor starts drawing too much current and the fuse will melt and break the circuit. Which is a good thing, otherwise the windings in the motor might short-circuit as the nonconductive coating on the wires degrades because of the heat.

Thanks for the grinding tip. Will take care not to heat the metal up too much by keeping each pass quick and maybe pausing in between.

I think the 12 amp saw still has a viable motor, it's the mechanism that keeps the blade tight that either got overworked or was faulty to begin with.