DIY grain thresher and huller

The last component of this year's grain

experiment is equipment. Backyard gardeners often skip growing

grains because of the complicated harvesting,

threshing, winnowing, and dehulling procedures. But Home-grown

Whole Grains

introduced two pieces of DIY equipment that I'm putting on my honey-do

list.

The last component of this year's grain

experiment is equipment. Backyard gardeners often skip growing

grains because of the complicated harvesting,

threshing, winnowing, and dehulling procedures. But Home-grown

Whole Grains

introduced two pieces of DIY equipment that I'm putting on my honey-do

list.

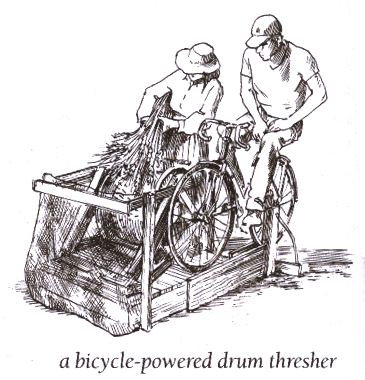

The first is a

pedal-power drum thresher --- I've stolen the picture from the book

just this once because I can't find anything like it on the

internet. Basically, a bicycle is hooked up to a utility-wire

spool. The spool is inside a collection bin of some sort and is

studded with xd nails, pounded in every two to three inches. One

person pedals, which causes the drum to spin, while another person

holds the grain heads against the drum. The nails pull seeds

out of the grain heads relatively quickly --- you can thresh about 40

pounds of grain in an hour with the DIY thresher.

If you're growing a

grain that has difficult to remove hulls (like buckwheat), you'll be

interested in Southern

Exposure Seed Exchange's method of converting a hand-cranked

grain mill into a DIY huller. Basically, you temporarily replace

the stationary disk on your grain mill with a rubber disk made by

gluing soft rubber onto a washer. With a bit of adjustment, your

mill will be able to crack the hull on seeds without breaking the grain

kernels. I can't find any pictures of this apparatus on the

internet either, but once we grow our buckwheat I'll give it a shot and

post about it.

| This post is part of our Homegrown Whole Grains lunchtime series.

Read all of the entries: |

Want more in-depth information? Browse through our books.

Or explore more posts by date or by subject.

About us: Anna Hess and Mark Hamilton spent over a decade living self-sufficiently in the mountains of Virginia before moving north to start over from scratch in the foothills of Ohio. They've experimented with permaculture, no-till gardening, trailersteading, home-based microbusinesses and much more, writing about their adventures in both blogs and books.

Want to be notified when new comments are posted on this page? Click on the RSS button after you add a comment to subscribe to the comment feed, or simply check the box beside "email replies to me" while writing your comment.

The drum is placed in line with the axis of the front wheel of the bike, implying that it drives the drum. But most bikes don't have front wheel drive.

What I would do (depending on the speed you need) is either put the back wheel against the drum and lift it from the floor, or put a smaller diameter roller on the axis of the drum and have the back wheel roll on that (in the latter scenario wou'd really need two parallel rollers to support the wheel properly, just like a home trainer adapter for a road bike).

Such a home training adaptor might make a good base to build your thresher from, now that I think about it.

First you have these machines where the crank just drives a friction brake. Generally not very comfortable or well-made, as far as I can tell.

Second there is this device where you clamp the back wheel axle of a bike into supports so that it presses onto a roller that drives a brake (or a generator). These devices are generally used by racing cyclists to train in indoors on their properly set up bikes. The advantage is that you can take the bike off and use it. A device like the pedal-a-watt works this way.

Might I suggest that you look into a recumbent solution? It's much more comfortable that a standard bike saddle. Of course you don't have to buy a bike like this. Just use the crankset from an old bicycle and build a comfortable reclining seat to drive it. This way you won't get a sore bum when you spend a couple of hours threshing or charging batteries or whatever.

Just remember that the continuous power than an average person can generate is not that high... Trained racing cyclists can sustain something like 250 W for the duration of a race, say a couple of hours. I'd be surprised if the avarage joe gets half of that!

On the safety question --- I suspect that the grain would actually be on a much longer stalk, say three or four feet. So the person holding it wouldn't really be close to the drum. That's probably a bit of artistic license to fit everything in a compact picture.

Good info about different types of bikes for pedal-power! I'm actually not sure what kind(s) Mark has. I like the DIY recumbant solution!

So far, we're hoping to use the pedal-power straight rather than turning it into electricity first. I haven't come up with many other things that can be run just by turning, though! (That's one of the reasons I liked the thresher so much.) Any ideas?

(That's one of the reasons I liked the thresher so much.) Any ideas?

Well, you could make a simple lawn mower (or a fancy one).

Or a washing machine.

Of course the best application for pedal power is a bicycle! But if you don't trust that on your local roads, what about a velocar? Or it's modern-day reincanation the utility quad ortrike?

You can find older machines at blue ox millworks.

Fascinating stuff, really.

Don't know if you're still looking for ideas on small scale grain threshing if so you should check out this YouTube video on grain thresher designs and winnowing.

http://www.youtube.com/watch?v=oDr8VF2QIPM

the drawing does imply the front wheel is intended for drive, but if you look at the bottom there is a cylinder below the crank. I believe the wheels are there for support only as it would be easier to attach the drive to the crank with a chain drive than it would to do a direct drive off the wheel.

as for safety, no it is not a safe design, but safety could be improved with the addition of protective cages around the drum and the person feeding the equipment. many innovations in farming have been about improving safety, and many farmers have been mauled and killed over the last couple centuries.

for increased safety, one might place some cages around the moving parts to keep the arms of the one feeding the grain well clear, one might also build a clamp to hold the grain stalks, but loading and unloading would make the process much slower. additionally one might look into rubber studs instead of rows of nails. these studs have been being used lately to pluck chickens, etc. in a number of commercial and diy projects. I am not sure how that would effect the efficiency of the machine, but it should improve safety a bit.

Lag screw floor flanges to the outsides of the spool ends with a pipe between them with short stubs out each end as axles. Probably good to weld on the stubs after threading them in. Rig a pipe frame and a treadle mechanism http://www.mhhe.com/engcs/mech/norton/norton/ch3/treadle_wheel/treadle_wheel.htm for a one person thresher. Wire loops are commonly used for rice. Drill holes and epoxy landscape staples into the drum face. See also: http://www.backtotheland.com/html/wheat_thrasher.html